- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Size: | |

|---|---|

| Material: | |

| Weight: | |

| Availability: | |

| Quantity: | |

RO-500L/H

KAIYUAN

8421219990

Product Description

The 500LPH Reverse Osmosis Brackish Water Treatment System processes brackish water with total dissolved solids (TDS) ranging up to 4000 μS/cm. The system's desalination rate reaches ≥97%, removing 99% of dissolved salts, contaminants, and other harmful substances, producing safe, purified water with TDS levels of ≤10 μS/cm.

With a water recovery rate of 50-75%, the system maximizes the amount of usable water from the brackish source, minimizing waste and improving water usage efficiency. It is designed with low energy consumption and automated control,ensuring cost-effective operation with minimal manual oversight.

Two-Stage RO System: The two-stage filtration process further enhances water purity, ensuring TDS ≤10 μS/cm in the second stage.

Wide Application for Industrial Use: Ideal for boiler feed water, food processing, and other industrial applications requiring clean, purified water

Minimal Maintenance: Equipped with automatic cleaning systems and easy-to-replace consumables like PP filter cartridges and RO membranes, ensuring long-term stability and low maintenance costs.

1. Capacity: 500L/H

2. Rated power: 1.5KW/H

3. Voltage: 110V/220V/380V, 50Hz/60Hz, Single phase/3phase

4. Desalting rate:>=97%

5. Water recovery rate: 50-75%

6. Conductivity of raw water: ≤400μs

7. Conductivity of pure water: ≤10μs

A. Regulating wheels

B. PLC Touch Screen

C. Two-stage RO system

D. PH adjustment anti-scale

E. Automatic cleaning system

F. Auto or manual control valve

G. U-PVC or stainless steel pipe

H. UV sterilizer/Ozone Generator

I. Dosing system/Water Softener

J. PE or stainless steel raw/pure water tank

K. FRP or stainless steel pre-treatment tank

Raw Water Tank → Raw Water Pump: The raw water is collected and pumped into the treatment system for initial filtration.

Quartz Sand Filter: Removes suspended solids, large particles, and turbidity from the raw water.

Activated Carbon Filter: Eliminates chlorine, organic compounds, odors, and other contaminants that could damage the reverse osmosis membranes.

Water Softener / Chemical Dosing System (Optional): Reduces hardness by removing calcium and magnesium ions or adds chemicals to further improve water quality.

Security Filter: Prevents particles larger than 5 microns from entering the RO system, protecting the membranes from potential damage.

High-Pressure Pump: Increases water pressure to ensure efficient operation of the reverse osmosis membranes.

Reverse Osmosis (RO) System: The core component that removes salts, dissolved solids, and other contaminants, producing high-purity water.

Pure Water Tank: Collects the purified water after the RO system for further treatment and storage.

UV Sterilizer / Ozone Generator: Further purifies the water by disinfecting it, killing any remaining bacteria, viruses, or microorganisms.

Precision Filter: Provides final filtration to ensure that any remaining particles are removed, ensuring crystal-clear water quality.

Water Supply Point: The purified, sterilized water is now ready for distribution or use in the designated supply area.

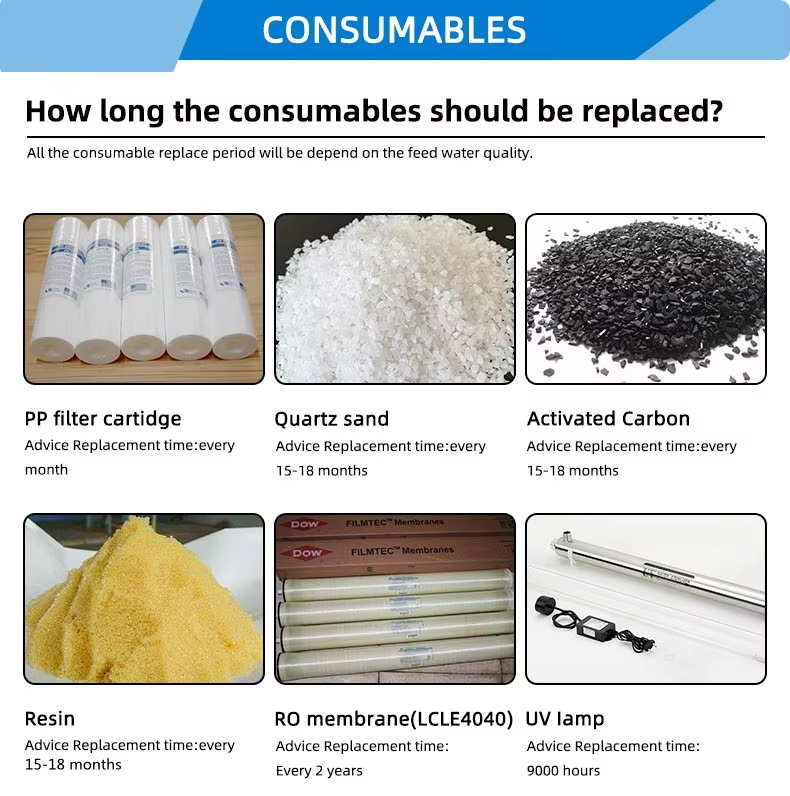

Consumables

| Component | Replacement Frequency | Notes |

|---|---|---|

| Quartz Sand | Every 18 months | Removes large particles and suspended solids. |

| Activated Carbon | Every 18 months | Eliminates chlorine, odors, and organic contaminants. |

| Resin | Every 18 months | Softens water by removing calcium and magnesium ions. |

| PP Filter Cartridge | Every 1 month | Essential for filtering finer particles; recommend purchasing 1-2 years’ worth. |

| RO Membrane | Every 2 years | Core component for desalination; replace as needed based on performance. |

FAQ

Q: Does the system require any chemicals for operation?

A: The system operates primarily through reverse osmosis technology, with optional chemical dosing or water softeners available to further enhance water quality and prevent scaling in the membranes. However, the system can function without the need for continuous chemical regeneration.

Q: What is the conductivity of the water produced by this system?

A: The system produces clean water with a conductivity of TDS ≤ 90-150 PPM, meeting the standards for safe drinking water and industrial use.

Q: Can the system be used in harsh environments?

A: Yes, the system is designed with high-quality, durable materials to withstand challenging environmental conditions. It can be used in coastal regions, industrial plants, and remote areas where water quality is a concern.

Our system stands out due to its energy-efficient design, long-lasting components, and minimal maintenance requirements. Whether you’re looking for a solution for boiler feed water, food processing, or other industrial uses, our system ensures high-quality output while reducing operational costs. The automatic cleaning system and easy-to-use PLC control interface simplify operations and help reduce downtime.

With our focus on sustainability, quality, and customer support, you can count on us to provide not just a product, but a comprehensive solution. From design and installation to ongoing maintenance, we ensure your system continues to operate at its best for years to come.

Choose Guangzhou Kai Yuan for reliable, innovative, and cost-effective water treatment solutions tailored to your needs.